Retail today moves faster than ever. Customers expect products to be available instantly, channels are multiplying, and buying patterns shift in real time. Yet many retailers still rely on outdated, manual, or intuition-led processes to decide what to stock and when. This gap between modern customer behavior and traditional planning is where AI-powered demand forecasting and inventory optimization are transforming outcomes.

At RBM, we help retailers move from guesswork to intelligence by designing systems that connect data, predict demand, and automate smarter inventory decisions.

Retail Demand Forecasting Challenges in Modern Commerce

Retailers operate in an environment where timing and accuracy are everything. Yet many organizations struggle with basic inventory planning, not because of a lack of effort, but because of outdated systems and disconnected information.

Most retail businesses still guess how much stock they need using manual spreadsheets, basic historical averages, or human intuition. While experience is valuable, it is no longer enough to handle today’s complexity.

Here’s what typically goes wrong:

- Popular products go out of stock, while slow-moving items pile up in warehouses. This happens because retailers cannot accurately balance fast-moving and low-demand inventory.

- Sales data is scattered across different systems, POS systems, eCommerce platforms, warehouse platforms, and supplier systems. Since this data is not connected, planners cannot see a full, accurate picture.

- Manual planning processes cannot keep up with fast-changing customer demand. Seasonal trends, promotions, regional variations, and online behavior shift faster than spreadsheets can adapt.

- Retailers often miscalculate demand trends, especially when buying decisions must be made months in advance. Many retailers must purchase inventory far before their products actually start selling, increasing risk when forecasts are wrong.

Common challenges include:

- Inaccurate demand forecasting leading to stockouts and overstock situations

- Limited visibility into real-time and future demand patterns

- Manual forecasting processes that fail to scale

- Inability to connect planning with warehouse and supplier execution

The result is a fragile planning process that breaks under pressure.

Business Impact of Inaccurate Inventory Planning and Stock Imbalances

Poor forecasting and inventory management don’t just affect operations. They directly affect revenue, customer trust, and business growth. When products are not available, retailers lose immediate sales. Customers who can’t find what they want don’t always wait, they move to competitors. Over time, this damages brand loyalty.

At the same time, money gets locked in excess inventory that doesn’t sell. Overstock increases storage costs, ties up working capital, and leads to markdowns and margin erosion.

The impact extends to customer experience:

- Customers become frustrated when items are unavailable

- Trust in the brand weakens

- Shopping journeys become inconsistent across channels

Internally, teams spend more time fixing stock problems than focusing on growth. Instead of planning promotions, improving assortment, or enhancing customer experience, teams are trapped in firefighting mode.

This creates a reactive business instead of a proactive one, and in modern retail, being reactive is expensive.

AI-Driven Retail Demand Forecasting and Inventory Optimization Approach

AI-powered demand forecasting changes the way retailers think about inventory, from guessing to predicting, from reacting to planning. The process starts with smart tools that analyze historical sales and current trends. This includes seasonality, promotions, price changes, regional differences, and channel behavior. AI models then predict what customers are most likely to buy in the future, not just based on past averages, but by recognizing complex patterns that humans cannot manually process.

Once demand is predicted, the system automatically calculates how much stock is needed. It considers:

- Lead times from suppliers

- Minimum and maximum stock levels

- Safety stock

- Warehouse capacity

- Channel-specific demand

The system doesn’t stay static. It continuously improves forecasts as new data comes in, learning from actual sales, changes in trends, and shifting customer behaviors.

This approach replaces slow, manual planning with:

- Continuous intelligence

- Real-time recalibration

- Data-backed decisions

The result is not just better forecasts, but a more resilient and responsive retail operation.

RBM’s AI Capabilities for Commerce Forecasting and Inventory Intelligence

At RBM, we build scalable forecasting and inventory intelligence systems tailored to retail complexity. Our solutions unify data, automate predictions, and strengthen operational execution.

We build systems that track and predict product demand, connect sales and supply chain systems, and deliver flexible forecasting models suited to different product types. Our commerce forecasting engine processes large data volumes and outputs actionable recommendations directly into planning workflows.

Demand Forecasting Methods

To ensure accuracy and reliability, RBM incorporates both quantitative and qualitative forecasting methods, blended into one intelligent system.

Quantitative Forecasting Methods

These methods rely on measurable data and mathematical modeling.

- Time Series Analysis

Uses historical sales patterns, seasonality, trends, and cycles to predict future demand. - Regression Analysis

Examines how demand changes in response to variables such as pricing, promotions, or weather. - Econometric Models

Combines economic theories and statistical techniques to understand how external factors influence demand.

Qualitative Forecasting Methods

These approaches incorporate expert insights where historical data may be insufficient.

- Expert Opinion / Delphi Method

Structured expert consensus to forecast demand for new or unpredictable products. - Market Research Studies

Surveys, customer insights, and behavioral data are used to understand future buying intent. - Sales Force Composite

Forecasts are aggregated from the experience and judgment of sales teams closest to customers.

By combining these methodologies within our AI models, RBM ensures that forecasts are not just data-driven but context-aware, delivering more reliable outputs across categories and channels.

Predictive Retail Analytics in Action, Turning Data into Strategic Advantage

Beyond traditional demand forecasting, RBM elevates retail planning through advanced predictive retail analytics. This means we don’t just forecast demand, we anticipate how future trends, customer behavior shifts, and external factors will shape demand, helping retailers stay ahead.

With predictive analytics, retailers can:

- Identify emerging demand trends before they spike, for example, detect rising interest in a product category across regions or customer segments.

- Understand how promotional campaigns, pricing changes, or seasonal events will influence demand, enabling proactive stock and marketing planning.

- Forecast demand at a more granular level, by store, channel, customer type, or region, to optimize inventory placement.

- Simulate “what-if” scenarios (e.g., price drop, holiday sale, supply delay) to evaluate potential outcomes and prepare accordingly.

By integrating predictive retail analytics, RBM enables retailers to treat inventory planning not just as an exercise in replenishment, but as a strategic tool, aligning supply, marketing, and operations to expected future demand.

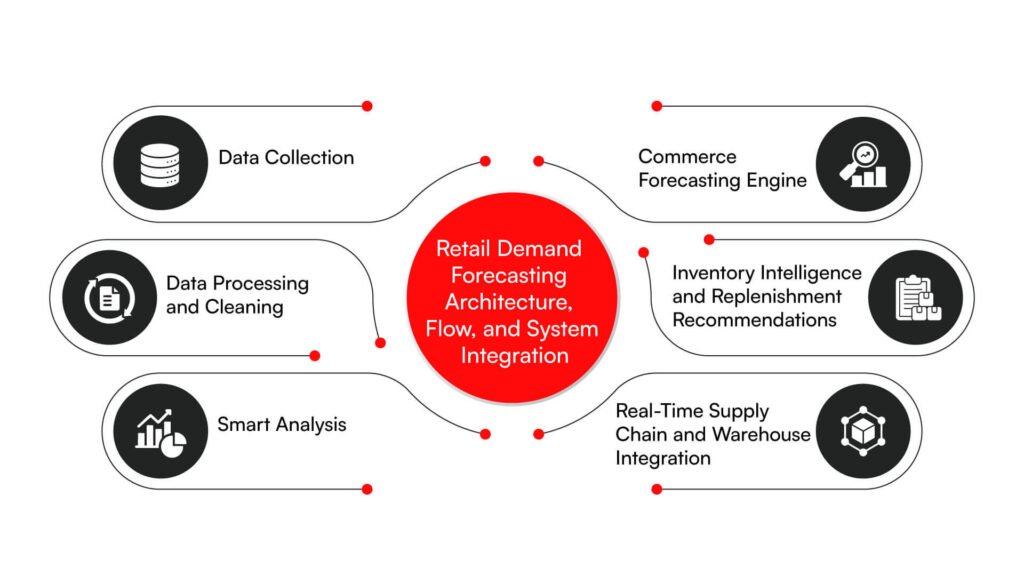

Retail Demand Forecasting Architecture, Flow, and System Integration

A strong technology foundation is what makes reliable forecasting possible. RBM designs clean, practical, and scalable system architecture flows that ensure predictions are not just accurate, but usable.

The flow typically works like this:

Step 1: Data Collection

Sales data is collected from physical stores, e-commerce platforms, marketplaces, and mobile apps. This includes orders, returns, browsing data, and promotions.

Step 2: Data Processing and Cleaning

All incoming data is cleaned, standardized, and organized into a usable format. This ensures that forecasting is built on accurate and consistent data.

Step 3: Smart Analysis

A smart prediction system analyzes the organized data, identifying patterns, seasonality, trends, and anomalies.

Step 4: Commerce Forecasting Engine

The commerce forecasting engine creates detailed demand predictions across products, locations, and timeframes.

Step 5: Inventory Intelligence and Replenishment Recommendations

The inventory system then calculates:

- How much stock to hold

- When to reorder

- Where to position inventory

Step 6: Real-Time Supply Chain and Warehouse Integration

All systems connect directly with warehouse and supplier platforms, ensuring that recommendations flow seamlessly into execution.

This architecture turns forecasting from a report into an operational engine.

Measurable Retail Outcomes from AI Forecasting and Inventory Optimization

Retailers that adopt AI-powered demand forecasting and inventory optimization experience measurable operational improvements.

You can expect:

- More accurate stock planning, reducing reliance on guesswork

- Fewer out-of-stock and overstock situations, improving both availability and margins

- Faster response to changing customer demand, including seasonal shifts and trending products

- Better business decisions backed by real data, not assumptions

Teams become more confident in their planning. Operations become smoother. Customer satisfaction improves. Capital is used more efficiently.

Instead of reacting to problems, retailers start preventing them.

Conclusion

Retailers need more than promises. They need systems they can trust at enterprise scale. RBM designs forecasting and inventory intelligence platforms that are built on proven, validated foundations. Our systems use trusted and proven forecasting methods, combined with modern machine learning, to handle complexity without sacrificing reliability. We implement constant system monitoring to maintain forecasting accuracy and to detect data anomalies or model drift automatically.

RBM follows secure data-handling practices across all layers of the architecture, ensuring that sensitive sales and customer data remain protected. Every solution is built on enterprise-level technology standards, designed to handle the performance, scalability, and compliance requirements of large retail operations.

Reliability is not an afterthought, it is designed into every layer of the system.

See how smarter forecasting can improve your retail business. Talk to our experts.